The Internet of Things is changing not only the face of industrial high-tech, but also the traditional manufacturing sector, causing companies and organizations to re-route and take a daring leap into the commercial world of tomorrow

One of the main challenges facing professionals today is the unavoidable need to contend with vast amounts of data. The pace and volume of data reminded Asaf Somekh, Yaron Haviv and Yaron Segev the force of the Iguazu waterfalls in South America. Combining the name of the waterfall – as an analogy for the powerful flow of data – and the term I/O from the worlds of data and computers, they named the company they founded in 2014 – Iguazio.

When they established Iguazio, Somekh, Haviv and Segev were already seasoned entrepreneurs and graduates of scientist-supported companies that had recorded commercial success in the high-tech field such as Voltaire and XtremeIO. Somekh, the company’s CEO, says: “If you look at the experience we had acquired, all the previous companies were oriented towards high-performance storage and applications which need to search through vast amounts of data.”

“We were familiar with the way people build data infrastructures and with the problems they contend with. One of the problems we identified was complexity: people attempt to build digital traffic in a completely different manner from the way things were built previously. In the past, data was used more for making business decisions by observing different cross-sections of the system, analyses and reports. The world of IoT has changed that picture however with an infrastructure that also receives data from external sources and is based on external events and information and not just on those in an internal vacuum. Combining these sources with the organization’s historical reports automatically leads to a sequence of business decisions.”

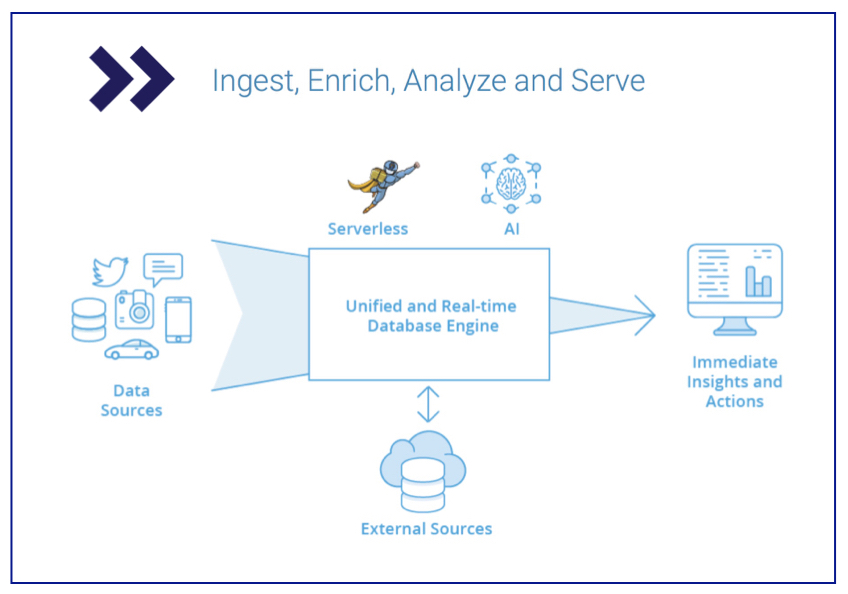

“Our goal was to develop an innovative big-data analysis and management solution that is intended for business and industrial companies and organizations. And indeed, Iguazio’s system, the ICDP (Iguazio Continuous Data Platform) enables us to gather all the information flowing into the organizational system and, using artificial intelligence tools, to conduct large-scale database-like actions on different kinds of databases. Analysis of the figures dramatically enhances organizations’ and companies’ ability to make real-time decisions.”

“From a technical point of view, Iguazio’s software serves as a ‘layer’ above the storage and enables real-time analysis of vast masses of data which constitute a reliable base of up-to-date knowledge for making business decisions. This a revolution in the management, storage and analysis of data. The efficiency of the development is made possible through a combination of big-data and cloud applications.”

‘We have 90 employees and are already selling the product worldwide – in Asia, the US and in Europe. We have had two funding rounds: the first of USD 15 million and the second of USD 33 million. Among the investors are the best venture capital funds in the country as well as strategic investors like the American telco company Verizon, the German company Bosch, and others.”

Artificial Intelligence: Learning and Deciding

“Let’s look for a moment at cases in the world of IoT that are highly relevant to this topic of productive maintenance in industry: for example, in the case of a client who owns factories with production lines – in the “old” world, a malfunction in one of the machines caused a stoppage of the entire production line. Such a stoppage would incur direct repair expenses and more significant costs of production cessation that hurt revenues. It is important to understand that one of a manufacturer’s biggest fears is a shutdown of the production line.”

“A large part of the market buzz around artificial intelligence is linked to the question of how, the use of IoT, can help prevent these malfunctions. Our solution, with the help of artificial intelligence, enables clients to identify that a malfunction is imminent even before it happens and stops the production line. Using artificial intelligence that analyzes historical events, the system automatically identifies the behavioral pattern which, in the past, meant that a malfunction was about to occur.”

“The world of artificial intelligence is made up of two parts: learning, and decision making based on gathered data, without an obvious connection between the two. Data is gathered from several machines of the same type after which the learning system tries to find a behavioral pattern. For example, if a machine starts heating up, then there is a very high probability that a malfunction will occur. At the end of the learning process, something called a “module” is created. The more data that is gathered over time, the better the modules know how to predict future events based on past occurrences.”

“We run the module that is created on the data gathered from the specific machine and give it greater context. In other words, more data on the machine itself is added to the module: what happened over the last 24 hours, the status of the machine’s other parts etc. For all this to happen, we need a system that will gather the data, with each type of information requiring different data-base capabilities. In the past, this world was simpler, but today it is highly complex because there are so many types of databases.”

“The gathering of data and its transfer to the area in which the learning process takes place, lays the foundation for the next stage – making the decisions in the field. Let’s say that the module predicts a significant malfunction: based on the module we also know how to deal with the problem. For example, the system will automatically change the speed of a certain component’s function so that production will continue while still preventing the malfunction. This is exactly the solution that we have built together with Microsoft and which is based on their cloud.”

“Our system enables receipt of the data, provision of data-base capabilities for these statuses and the performance of historical analyses – all in a rapid, simple and high-performance manner. It is all done in a closed loop within Iguazio while using cloud technology up to the learning stage – and application at the end, i.e., the client in the factory.”

“It is important to state that there is certainly room for including human thinking in the decision-making process. The world of artificial intelligence is still in its infancy and humans still possess a wider context. In our example, a human would know that the production line could complete the job within a few hours thereby enabling the repair of the malfunction to be done at greater leisure.”

Prediction is Protection

“A good example of the work we are doing is a client of ours in the automobile field who asked us to develop a system that would predict the life capacity of the vehicle’s battery. His company has a fleet of thousands of vehicles and the possibility of preventing flat battery situations could save them a lot of money. Using our system, data on all the batteries is gathered and their behavioral patterns enable a conclusion to be drawn about which battery is going to die within the next two weeks and for a warning to be issued to the fleet manager.”

“The market of connected vehicles is still evolving so that even such a seemingly simple prediction has significant added value. We are capable of supplying different levels of predictions – regarding safety for example – and this has tremendous importance, among others because decisions in autonomous vehicles need to be made more quickly.”

“Artificial intelligence has also become an integral part of the corporate and organizational world in the field of telecommunications. With our help, an Asian mobile operator introduced prediction capabilities into its infrastructure. The company is now able to predict the failure of routers and switches in a specific network within a few hours if it doesn’t make an adjustment to the network. In the cyber worlds, this module is returning in many markets.”

“The world of cyber security is a good example of the extremely important use of data gathering and analysis systems. Certain types of cyber attacks use viruses that appear innocuous, but which can sometimes cause hundreds of thousands or even millions of computers to attack a specific site with the objective of causing it to crash.”

“In an after-the-fact analysis aimed at understanding what happened, previous traffic patterns can help us understand how the attack was created and executed. In hindsight, I can also identify the initial transfer of bots and the beginning of the attack, and to block computers and sites that may repeat the same behavior even before the next attack takes shape. This is a dramatic change in the organizational capability of contending with cyber-attacks.”

“There is currently tremendous ‘hype’ around artificial intelligence. There is no doubt that it has advanced significantly since I studied the topic in the 1990s, but we still have a long way to go to realize its tremendous potential.”

>>>

Listening to Machines

Augury is Saar Yoskovitz‘s and Gal Shaul’s first startup. “Saar and I both served as officers and got to know each other at the Technion”, says Gal Shaul, the company’s current CEO. “I studied computer sciences and Saar studied physics. We worked in high-tech for several years and always talked to each other about start-ups. A few years later, when we felt sufficiently comfortable in the world of technology, we started working together on an idea for a start-up of our own.”

“During the first three years we sat in a garage and developed the technology. It was only in 2014, after things started coming together and moving forward, that we founded the company and left the garage. It takes time to understand how to be an entrepreneur, to identify the market and your product.”

The development of advanced manufacturing technologies involves a mix of changing work environment with unique challenges”, says Gadi Hornstein, Senior Director IoT and Mobility Sector at the Innovation Authority. “The companies supported by the Authority develop solutions that combine creative thinking and advanced operating perceptions which economize manufacturing processes while increasing productivity and enhancing product quality. This leads to an improvement in competitiveness and enhances the companies’ chances of establishing themselves in Israel and reviving local technological manufacturing.”

“It’s fun to come to investors as Israeli technological entrepreneurs but it also involves more than a few challenges. You need to know what you do and don’t understand. In the company itself we are also heavily invested in organizational culture which, among other things, means that we both believe in building the right team to enable us to design the products and we invest a lot of thought in the company values. We already have 75 employees – in New York and Israel – and we are engaged in Product Engineering Innovation”, says Shaul.

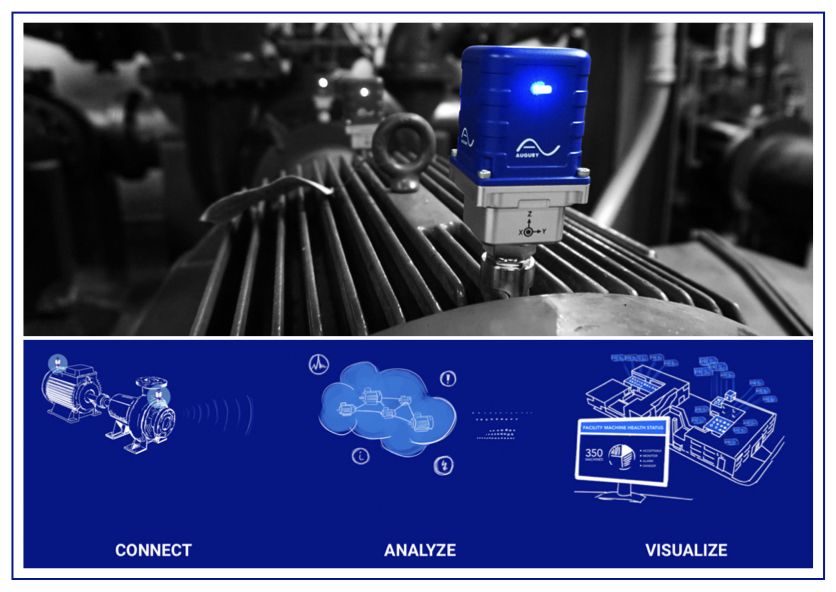

“We are developing a system that ‘listens’ to the machines and that according to the sound they produce, predicts malfunctions that may occur in the production line. This is also the origin of our company’s name – Augury is the Maori word for ‘prediction’ or ‘forecast’. Our product is highly technological and, as is fitting for IoT products, includes hardware, software and algorithms, which means that there are also aspects of plastics and electronics as well as the sensors which are placed on the machines we check.”

“The science behind our method is listening in order to predict malfunctions”, says Shaul. “The idea has existed since the 1990s and led to the development of a maintenance method which relied on predicting malfunctions according to the sound produced by the machine. This method is relevant for any machine: for example, if a car has a noisy timing belt – regardless of the type of car, it will produce the sound of a noisy belt. The idea that mechanical devices have sound patterns which can be used, has until recently been stuck in the end markets – high-cost and isolated off-shore power stations for example. The previous method included expensive vibration sensors and manual analysis by a vibration analyst – a mechanical engineer with years of training in analyzing vibrations – who analyzes and produces a report on the state of the machine. This solution was so expensive that it was worthwhile being used only if the alternative solutions were even more costly.”

“When we started out, we looked at the problem again and realized that it would actually be possible to employ this method in any machine – if we could only make it more financially viable. We also understood that the solution lay in the expertise of analyzing the vibrations. In other words, we solve both the cost problem and provide a solution for the expertise –the solution we offer is to do this using sensors and computers and not analysts. This both increases credibility and provides the teams with peace of mind.”

“One of the first problems that entrepreneurs encounter is how to obtain the funds with which to find the solution to a problem. We received support from the Innovation Authority almost from the outset, both through projects and via introduction to various entities, and their involvement certainly helps creates a positive and credible image in the eyes of investors. We also submitted a funding request this year for a relatively small project that is part of the development and this support enables us to build things which would have otherwise been pushed down the list of priorities.”

“Despite having overseas investors, we have chosen to keep all the R&D in Israel because of the high-quality, enthusiastic and talented local professionals. Our technology is extremely complex and includes both hardware and software, but we found everything we needed in Haifa and have built a great team. Our operations in the US are in New York and not in Silicon Valley.”

Faster, Cheaper, More Efficient

“Our clients come from the classic industry where the historical aspiration is innovation: to make things cheaper, more efficient, and of better quality. Innovation in manufacturing is what has enabled us over time to enjoy today’s quality of life. This is a field in which innovation is a natural part. The combination of high-tech – advanced technologies – and innovation in the world of manufacturing is called Industrial IoT and we view ourselves as one of the companies bringing a new wave of innovation to manufacturing and other industries.”

“The technological solution we have created at Augury allows a new approach to the problem of machine maintenance, but the challenge is that to do so, you need to work with the industry’s large organizations and explore all the possibilities until you find a technological solution with algorithms. So, we knew that later on we would need to examine how the interface would work with the software.”

“Every physical movement of hardware creates a pattern of noise and vibrations. We place sensors on the different areas of the machine and, with the help of artificial intelligence, identify its mechanical state. In other words, using our unique technology, we actually decipher its ‘speech’. In practice, the challenge is how to gather vast quantities of big-data and transmit them to the cloud – while solving problems of connectivity and bandwidth – up to the stage of machine learning. We know how to solve big-data problems of this scale and after we receive the results about the state of the machine – identifying an anomaly or a specific problem – we provide the client with the information. It can be done in whatever way is convenient for them: e-mail, SMS or telephone – as long as the technician or person responsible for the machine understands exactly the problem that needs fixing.”

“Approximately a third of the machines that we check will need some sort of repair within six months. In about ten percent of the cases, the examination reveals that if action is not taken, the situation will only get worse. The earlier the problem is identified and addressed, the more efficiently it can be successfully resolved without shutting down the production line. Sometimes, a fault that costs 200 dollars to repair today may, if left unfixed, cause in the future a bearing to break or an axle to collapse, in other words, more serious and expensive damage.”

“The main challenge associated with using the IoT is that because of the speed and the large volume and scope of data involved, all information automatically becomes big-data. Fortunately, there are many tools in this field that, when used wisely, can contend with anything. What is important to remember is to focus on resolving the existing problem. Our approach is suited to situation management and allows for flexibility and quick changes.”

“We sell a service of real-time machine monitoring. The service is comprehensive and includes support from beginning to end: we start with the building of a program for the facility with the help of our team of experts, supply hardware, take care of installation and provide the client with a dashboard that features a situation report of the machines, including warnings about changes in the situation of each machine. Each client is regarded by the team individually, and we study him to ascertain what is correct and incorrect to do in his specific case. This is a process that takes time because the companies that work with us need to change their work methods, organizational processes, technology, and also their thought patterns. Only following this ‘destruction’ of the current situation is a new beginning possible.”

“Our clients are large corporations, mainly in the American market, in a range of fields from food, manufacturing and equipment maintenance companies – including the Israeli company Hadera Paper and the American giant Pepsico. We started with machines that are not part of the manufacturing process but that constitute the peripheral equipment, and we are now turning to production lines.”

“As of today, we are more focused on the commercial possibilities – preventing major malfunctions and stoppages – which save time and money, but our vision is to be present in every device that has moving parts, from heavy equipment to coffee machines, and listen to it. Moreover, we also want to be the analytical motor that will enable this listening and its resultant insights. All machines need to be more reliable and every organization needs to be capable of solving problems. We are here for the long haul with a vision for the long-term future.”

“There are two trends moving the revolution in industry: On the one hand, the internet is penetrating with cheaper sensors and communications and the capability to transfer and process large amounts of data at low cost. Sensors are becoming cheaper and smaller, making it easier to transmit and process data. On the other hand, innovative artificial intelligence technologies are enabling prediction and production of smarter insights that were simply not possible in the past.”

“We see these changes in the United States, China, Israel, and to a certain extent, also in Europe. These trends are so significant and prevalent that they can’t be stopped, and companies must accept these new technologies in order to succeed. The challenge is in tailoring the technologies to the needs and capabilities of the organization and the ability to contend with risks such as the information security challenge.”

‘The most efficient way for these technological trends to gain true expression is cooperation and joint learning between high-tech companies like ours and traditional industry – and this is our approach at Augury.”