Farsighted vision based on bio-convergence is driving two Israeli companies towards the development of innovative materials: Seevix has developed a fiber inspired by spiderwebs – the ‘Holy Grail’ of the world of materials – while Enzymit designs and builds enzymes, biological nanomachines capable of creating any material.

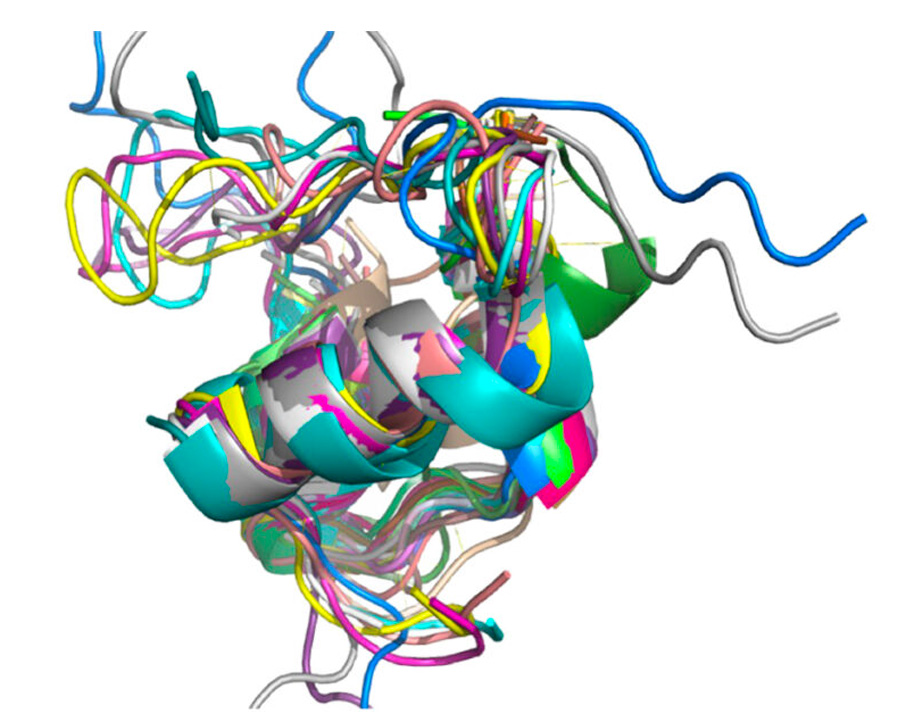

“Every cell on earth contains thousands of different enzymes which are, actually, machines working inside the cells”, explains Dr. Gideon Lapidoth, co-founder and CEO of Enzymit. “Some of them break down food while others build new materials. Without these machines, life as we know it could not exist”.

Enzymes are nature’s production machines: “You put something in on one side and something else comes out on the other side”, Dr. Lapidoth explains. “For example, in the process of photosynthesis, plants take CO2 (Carbon Dioxide) from the air and, using solar energy, convert it into sugar. In other words, the enzymes convert solar energy into chemical energy. At Enzymit, we do what the enzymes do, only artificially and more efficiently. Moreover, we can also produce materials that don’t even exist in nature”.

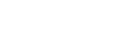

In a study he conducted at the Weizman Institute, Dr. Lapidoth examined ways of designing proteins that can serve as biological nanomachines capable of building real materials, atom by atom, just like machines in the real world. “Nanotechnology enables us to play with atoms and molecules to produce new materials for various fields – for example, food, cosmetics, and pharmaceuticals. So, instead of using standard chemistry, we create enzymes that don’t exist in nature to act as machines that will produce these materials for us”, he explains.

From Chemical to Biological Production

At the forefront of Dr. Lapidoth’s work is the aspiration to create materials in a process that is better, cheaper, and more efficient than what is possible using chemical production – the predominant form of production in the modern world. “Everyone realizes that biological production is greener and better for the environment than chemical production which causes pollution”, Dr. Lapidoth explains. “The problem lies with the cost: fermentation-based biological production is very expensive. For example, biological fuel is more expensive than fuel produced from oil. However, an enzymatic process allows us to produce fuel at a lower cost than is possible today and, no less important, it doesn’t pollute the environment”.

Enzymit has built and continues to develop a technological platform and computing capabilities, developing algorithms that design new proteins. “Imagine, for example, plastic based on sugar or even CO2, instead of oil”, Dr. Lapidoth suggests. “This could mean a limitless supply of raw material that is also biodegradable.

“We examine this from an engineering angle and then design an enzyme capable of generating a chemical reaction. For example, an enzyme that can convert CO2 into sugar, or turn simple sugar (monosaccharide) into a more complex and expensive material”, Dr. Lapidoth says.

The initial materials developed by the company are already on the market. The first of these is a hyaluronic acid produced in an enzymatic process from a monosaccharide. Hyaluronic acid has many uses in the cosmetics and health industries and is traditionally produced primarily from chicken comb or bacteria.

“The hyaluronic acid we produce is cleaner and of higher quality than the existing acid. The process is low-cost, quick, and is performed without cells, yeast, or bacteria”. The goal for the future is that the process will start with white sugar rather than with CO2.

Enzymit is also working on an enzymatic process of converting cheap oils such as canola or palm oil into oils that possess qualities of olive oil or animal oil, but without involving live cells or animals in the process.

The Magic of Enzymes

The method’s advantages are clear: it is just as efficient as chemical production, but without all the environmental damage and all the unhealthy conditions, and is performed efficiently, within several minutes or just a few hours. “It’s actually like magic”, says Dr. Lapidoth. “An enzyme is like a printer: you put in the ink and something else comes out the other end. The computation side of things is the planning of the printer and its production. At Enzymit, we took the old trial-and-error process and turned it into a planned engineering process.

“Our vision is to build a bioreactor process whereby CO2 is fed into one side and starch, cellulose, or plastic is emitted on the other side. I know it will work – at present it is just a question of budget. I am sure that in several years it will be possible to do this cheaper than in any other, more cumbersome method.

“Instead of growing huge fields of cotton to produce cellulose, I will have a bioreactor that will take CO2 and convert it into cellulose. Ultimately, it is all just a chemical process in which a very cheap raw material is converted into a product that has value. I am sure that we can build a machine that converts CO2 into food or fuel.

“Everything is innovative here, because this technology didn’t exist three years ago, and its application was impossible until recently. For example, we needed Artificial Intelligence to design the enzymes. While until recently we worked for years on each enzyme, today we can design it in only a few days. This technology is a ‘game changer’ that will transform everything”.

Dr. Lapidoth believes that this technology can solve many problems on a global scale. Until now, most of the applications in this field were in the world of pharmaceuticals, but Enzymit has chosen to focus on industrial biotechnology i.e., on the world of manufacturing. “I think primarily about how to cut the cost of manufacturing “, he says, “because no one wants to buy nylon from sugar that costs six times more than regular nylon. There is no limit to what can be done with what we have developed by mimicking materials that exist in nature and industry and creating entirely new materials”.

The company’s technology is, as of today, based on several disciplines: computer science, biochemistry, organic chemistry, and microbiology. “We are currently focusing on the cosmetics and food markets”, Dr. Lapidoth describes. “We decided to initially produce special and expensive things that can be profitable even when produced in small quantities”. The next stage is to increase the scope of production – to factories. Because the product is identical to what exists in nature, even regulation is not a problem”.

“The Innovation Authority is supporting us”, says Dr. Lapidoth. “They strongly believe in our vision and in the connection between biology and computer science. What is good about the current era is that it used to be very expensive to set up biotech and now it costs a lot less”.

Nevertheless, Dr. Lapidoth refers to shortfalls on the logistical level. “We produce enzymes by computer design that generates a digital DNA sequence which then needs to be manufactured and inserted into bacteria. This is a very established technology that has existed for 40 years. It will eventually disappear when it becomes possible to produce enzymes without bacteria. Our solution is extremely creative”, Dr Lapidoth concludes. “I fully believe in the technology – it’s clear to me that it will work. It has to work”.

“The Innovation Authority harnesses the abilities of Israeli scientists to develop new compounds via synthetic biology methods, while drawing inspiration from things that exist naturally in the environment. These scientists employ their imagination to create improved and inexpensive enzymes that act more efficiently than those that exist in nature. These abilities constitute a launching pad for the creation of a wide variety of initiatives in the fields of food, environment, energy and others”.

Dror Bin – CEO, Innovation Authority

As Strong as Metal, As Flexible as Rubber

Dr. Shlomzion Shen, CEO of Seevix, also talks about being inspired by nature, leading to the creation of an entirely new material. Dr. Shen founded the company in 2014 together with Dr. Shmulik Ittah, who, during his studies at the Hebrew University, researched the DNA sequence of the spiderweb fiber.

“Spider silk is a much sought-after material in the world of materials because of its unique quality that exists in no other material – the capability to absorb energy”, Dr. Shen explains. “The fiber is both strong and elastic – and the correct combination of strength and elasticity is considered the ‘Holy Grail’ of the materials world. It’s not the strongest material or the most elastic – but its combination of the two qualities is ideal for the capacity to absorb energy.

“Nature embodies 4 billion years of R&D from which we can learn”, Dr. Shen elaborates on biomimicry, the human imitation of phenomena in nature. “A decade of research conducted at the Hebrew University, regarding the DNA sequence of spider silk led to a registered patent licensed by the company which is used as the foundation for our work”. Seevix has come a long way since then, and today, the company has sixty patents in this field.

The process developed by the company involves the capability to insert the unique spiderweb-based genetic code into a bacteria micro-organism and to teach it how to produce the desired raw material. The resultant proteins self-assemble as nanofibers, which coalesce into a kind of small sponge with a diameter of half a micron.

“This is our raw material, which we call SVX”, says Dr. Shen, “and it is produced spontaneously inside the micro-organism. The levels of sophistication and application are higher than any other existing material. This is much more than just a protein. This material has physical qualities of strength and elasticity, and its surface area and structural sophistication enable us to use it as a ‘delivery device’ i.e., to load SVX with different hormones, molecules, and proteins for gradual and local release”.

“Although my doctorate is in biology, I worked for most of my career in business development and management, so I have not only a technical and biological background but also a business background. I love this combination because it allows me to bring science to the market and to understand how to do business with it.

“At Seevix, we made the full transition from licensing the technology from the university to identifying a commercial logic, and then engineering scale-up to make it commercially applicable. Initially, we had to contend with the challenge of transforming this expensive raw material made from protein into something that is economically viable. To do this, we recruited the smartest minds. A startup has to begin with an initial application and here too, there was much thought and learning which yielded numerous insights”.

Skin Spidermen

Perhaps surprisingly, SVX’s first commercial application will be in the field of cosmetics. Seevix uses SVX to produce skin creams and serums, where it is combined with hyaluronic acid, retinol and other ingredients that are released gradually on the surface of the skin or hair. The final product has a dual effect: it acts as a long-term anti-aging agent and immediately strengthens and tightens the skin but with the elasticity allowing the face to maintain natural expressions. “We conducted numerous clinical trials and the results are amazing”, says Dr. Shen excitedly. “Our material creates capsulation and releases beneficial substances on the hair and skin surface over the course of eight hours”.

Another advantage this material has is the fact that it is environmentally friendly and even vegan. Despite its inspiration from the spiderweb’s DNA code, no animals are used in making the material, and it is produced via fermentation in a completely closed-off process. Furthermore, this is a biodegradable material that breaks down into proteins when buried in the ground.

“We will enter the market soon with these materials”, says Dr. Shen, “and start creating revenues for the company in the beauty sector. I think what we are doing here is amazing: the ability to create an immediate sensation and feel a stretching effect with all the formulas that protect the skin against the sun together with an antioxidant effect, without the need to inject anything into the body. As CEO, seeing a company bring a product to market and becoming profitable is fantastic and the imagination soars in many other directions.

“This raw material can be used for many things and that’s why we are collaborating with different companies. We don’t plan to manufacture the final products but rather, to provide solutions for different sectors and to cooperate with companies that know how to manufacture and sell the final product in their industry. We will be the experts in our raw material. For example, at the 2020 Olympics in Tokyo, the Japanese sports company ASICS presented applications of our technology in sportswear and sports shoes as a material that improves performance and is friendly to the environment”.

Another application Seevix is working on with the support of the Israel Innovation Authority is cultivated meat. In this case, the material developed by the company acts as a scaffold that enables the cells to grow faster and better as well as to live longer. “The Innovation Authority is such an important platform for startups in Israel. It has helped me since the beginning, even before the founding of the company, and provided funding, the constellation of the consortium for cultivated meat, and generally with many other things”, says Dr. Shen.

“Our development is based entirely on bio-convergence. We have biologists, chemists, materials professionals, and production personnel working at our facility in Jerusalem. It’s very enjoyable to work with a diverse range of people from different disciplines who work together. It’s not easy because everyone speaks a different language, however, the results prove that we’re on the right track, it is also an amazing experience”, Dr. Shen says. “On a global level, our vision is to bring new sustainable and environmentally friendly materials as part of a solution for the existing and intensifying climate problem. On the smaller, Israeli level, one of my dreams is for a large production plant here that will manufacture thousands of tons of our material, not just for the cosmetics sector, but also for the textile industry and, of course, for protective products, because of its strength and elasticity”, Dr. Shen concludes. “This material has so many good aspects that enable it to be used by many different industries, owing to its biological and mechanical characteristics. There are not many materials that have such amazing overall qualities”.