In a reality where the dairy and meat industries are significant factors in the global climate crisis, the brightest minds are looking for solutions for human protein consumption. The combined efforts of science and technology have produced alternative proteins, a field in which the Israeli food-tech industry has already gained a notable global reputation.

Some figures that are important to know:

- The global beef industry produces between 14%-20% of greenhouse gas emissions – more than the entire automotive industry.

- Almost 70% of the world’s farming areas are used for growing animal food.

- Only one-ninth of a chicken’s weight is used for edible protein. This figure is even lower for a cow.

- 12,500 liters of water are needed to produce 1 kg. of meat.

- 10 calories of vegetation are needed to produce 1 calorie of chicken meat.

The Hub that Identified the Trend

In 2011, the Strauss Group established ‘The Kitchen Hub‘ in conjunction with the Israel Innovation Authority. The hub aims at promoting companies developing innovative food-related technologies.

The hub was established as part of a strategic process undertaken by Strauss that identified trends occurring in the food industry. An analysis of these trends led to the understanding that technology would occupy a central role in the food market’s development. Among the insights gained was that the food industry is also responsible for creating solutions for the environmental ramifications of its activity, both out of a responsibility towards the planet and because consumers are becoming more sophisticated and critical. The upshot of this consumer awareness is that businesses that fail to produce products that are healthier and more sustainable will see its customers leave in favor of those that do. And, if technology can provide the solution, who better to do so than the ‘Startup Nation’?

Jonathan Berger, Director of ‘The Kitchen Hub’, says: “We understood the need to incorporate technology in the food industry and we were among the first in Israel to enter the food-tech field. We quickly realized that entrepreneurs often have good ideas, but they lack the funding and real-world experience of commercial-scale manufacturing necessary to implement them”.

The figures speak for themselves: The hub opened under the auspices of the Innovation Authority in 2015 and in December 2021 ended its seventh year of operation with proposals submitted from a total of 970 companies, 22 companies that grew in the hub, 250 jobs that it created, six factories established by hub companies, and over 220 million dollars raised for its companies. Part of this was invested by Strauss and part by other investors, both foreign and local.

“The Innovation Authority’s support allowed us entry into high-risk investments and to set up companies that would have been unable to receive initial stage funding from other investors”, Berger explains. “After we took on the risk and grew the companies, other investors also stepped in”.

“The state’s willingness to actively invest solves a significant market failure of investors who don’t like investing in the early stages of a company. Thanks to the hub, we can successfully establish whole companies from very preliminary stages and have become “Company Creators”. 9 of the 22 are companies that we’ve established from scratch. In other words, we identified the technology, brought in the best professionals, and established a company.

“Thanks to the Authority’s funding and the ecosystem that has been created here, Israeli global reputation in the food-tech sector is second only to that of Silicon Valley. By the way, the funding sums raised in this sector in Israel are the highest in the world. The Authority’s contribution is, in my opinion, not just to the ecosystem – by creating jobs and factories, and as a solution to the market failure – but also, in the creation of the State of Israel’s competitive advantage over other countries”.

One of the areas in which Israeli innovation has come to the forefront is the field of alternative proteins – proteins that are intended for human consumption but are not based on the consumption of meat or milk.

“Humankind is paying a high price for cellular agriculture, where cells are used to create protein. Alternative protein can be divided into three types:

- Plant Protein – soybean which has existed for at least 30 years, peas, chickpeas, or other plant proteins from which protein substitutes are prepared.

- Precision Fermentation – a process whereby an organism is programmed to produce a protein.

- Cultivated Meat – where cell tissue is taken from a cow’s umbilical cord, grown in the lab, and used to produce clean meat that doesn’t involve harming or killing an animal.

Cell Sampling Becomes Tons of Meat

“Today’s beef industry begins with herds of cattle that need expansive grazing areas and large barns”, explains Didier Toubia, co-founder, and CEO of Aleph Farms, that was founded by ‘The Kitchen Hub’, on the basis of the technology developed by Prof. Shulamit Levenberg from the Technion. Creating new gazing areas is considered one of the leading reasons for deforestation in tropical regions. Herds of cattle that are fed without grazing pastures need huge quantities of soybean and corn which in themselves require large areas to grow. The cows also emit a quantity of methane gas that influences the trends of global warming.

The crowded conditions in which the animals are kept create an ideal environment for the spread of infectious diseases which means that large quantities of antibiotics must be added to their food. Various hormones are also injected into the cows to further enhance the quantity and texture of the meat.

Ultimately, an animal is a machine that converts plant energy into animal energy – and does so in an extremely inefficient manner. According to Toubia, in the future, industrialized production factories will be replaced by cultivated meat production facilities that will be capable of supplying the same product with a fraction of the resources and energy needed to produce conventional meat. According to Aleph Farms’ worldview, cultivated meat will complement the sustainable farming methods for growing animals for meat, and not replace them. This process has great significance not just for the Israeli meat consumer (85% of the meat he/she consumes comes from overseas), but also, for the global beef industry.

Cultivated meat has clear ecological advantages. As mentioned above, raising cattle for meat is the most pollutive food, whereas growing cultivated meat will save much of this pollution and will significantly decrease water and land consumption, and greenhouse gas emissions.

Yet another advantage is that only the edible tissues are grown in a cultivated meat production facility, thereby obviating the need to grow an entire cow, most of which is ultimately disposed of. Furthermore, the production enables to recycle some of the ingredients, thus reducing waste and lowering costs.

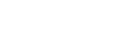

Aleph Farms, currently operating at the Rehovot Science Park, is one of the leading companies in the field of growing cultivated meat. Its technology is based on research conducted in the lab of Prof. Levenberg who studies tissue engineering for medicine. Tissue consists of several types of cells and needs some kind of exoskeleton made from extracellular material to grow in 3D form. Levenberg and her students found a way to produce such an extracellular matrix from edible plant protein.

This method served as the basis for Aleph Farms, founded in 2017 as part of ‘The Kitchen Hub’. It quickly raised millions of dollars from investors and opened a facility that today employs 80 people. One of the investors and advisors in the most recent round of fundraising (held in July 2021) that was led by ‘L Catterton’ and the venture platform of ADQ, a UAE sovereign, was Hollywood actor and climate activist Leonardo Dicaprio. The company’s first product – a thin-cut beef steak – is scheduled to be launched on to the market around the end of 2022, pending regulatory approval. At the same time, a thicker cut of meat was developed in Levenberg’s laboratory – a kind of marbled ribeye steak that includes muscle and fat cells, and which is produced using a 3D bioprinter. This technology gives Aleph Farms the ability to produce any possible cut of meat.

All that is needed to produce cultivated meat is a tiny sample of cells the size of a grain of rice containing cells capable of sorting themselves into different types and rapidly reproducing. What starts as several microscopic cells becomes, within 3-4 weeks, a juicy steak. The original cells sample can create thousands of tons of cultured meat. In principle, this technology can be used to produce meat from any animal – beef, poultry, and even fish.

Toubia believes that the revolution will eventually be part of every home and will have far-reaching economic ramifications. According to a market survey conducted by the company, approximately 80% of the population are estimated to be interested in tasting cultivated meat. Among the younger generations, this figure stands at 90%. The motives for this are varied: younger people will adopt cultivated meat because of aspects related to sustainability, morals, and preventing cruelty to animals. Older generations are more interested in controlling the amount of saturated fat they consume, and aspects related to health and the absence of antibiotics in the production process.

The cultivated meat industry has significant importance, not only on the level of creating jobs and sustainability, but also from the aspect of food security: “Today, only 12% of the meat consumed in Israel is produced here and the rest is imported. We can significantly increase the quantity of beef grown in Israel and build a new economic growth engine”, Toubia claims.

The company’s creed is a combination of innovation and impact aimed at bringing about a change. “The food industry’s problem is a systemic one. Inefficient use of resources and a lack of an organized plan for managing proper nutrition. There are enough resources in the world to feed the entire population, but we don’t utilize them properly. Today’s food system is not built to feed the existing population or, naturally, that of the future. We throw away 30% of the food we produce, while 900 million people suffer from a lack of food security”, Toubia says.

A Bottle of Milk from the Future

In April 2020, exactly when the Covid pandemic reached Israel, an Israeli startup called Imagindairy was founded in ‘The Kitchen Hub’. Dr. Eyal Afergan, the company’s CEO and co-founder together with Dr. Arie Abo and Prof. Tamir Tuller, tells of the company’s beginnings: “I tried for years to change and improve my diet in different ways but, like many others, wasn’t very successful, mainly because the existing alternatives to healthier products are nothing like the real thing. In practice, as consumers, none of us are prepared to compromise on the flavors and textures we love, and therefore only a few people succeed in sticking to their desired diet over time.

“Therefore, when the idea came up to set up a company that would develop milk proteins for a product with the same flavor and texture as those based on regular cow milk, including all the nutritional values, and even be healthier – and all at a similar price, it seemed obvious to me that this is the perfect solution. The whole change occurs in production without the consumer being required to compromise at all. I believe that this is how real sustainable change is created”.

There is a high level of animal protein consumption today. In essence, protein is the real nutritional advantage of milk consumption and is responsible for the texture and the sensation of cheese texture in our mouth. Nevertheless, it is important to remember that only 34 grams of each liter of milk is protein i.e., just 3.4%. The rest is fat, lactose, water, etc.

Imagindairy takes micro-organisms and teaches them to produce milk proteins that are identical to those of cow’s milk. While in the plant protein industry they try and take plant protein – that can originate from peas, soybean, or any other plant – and force it to behave like milk protein, Imagindairy uses protein that is identical to that of cow’s milk as the base for constructing the product, while maintaining full control over its makeup and nutritional value. This enables them to produce milk with the same quantity of protein and fat as cow’s milk but without any cholesterol or lactose.

Imagindairy’s technology is based on precision fermentation. Afergan explains: “This means that we produce a single protein from fungus or yeast, separate it and use it to construct the product. For example, if I want to produce a whey protein – that is considered the best protein from a nutritional point of view – I go to the online digital database, download the encoded genetic sequence for that protein, and synthesize it into a DNA segment. I then insert this segment into the DNA of the fungus or yeast, and they start replicating and producing the protein. At no stage of the process do we use a cow.

“We guarantee to provide a product with identical flavor to that of the milk products we are familiar with today, and to enable consumers to benefit both from the nutritional advantages of milk and the environmental advantages of preserving animals and the planet, as has been achieved with consumption of vegetable products. For example, while the global beef industry produces between 14%-20% of greenhouse gases, in the worlds of precision fermentation these are reduced by 95%-98% to negligible levels.

According to Afergan, one of this industry’s biggest challenges is that of production costs. The challenge is to reach a stage at which a bottle of alternative milk is sold to the consumer for 5-10 shekels, similar to that of cow’s milk. It must be noted that cow’s milk is a subsidized product in almost every country worldwide.

To successfully meet this challenge, the company combines advanced biotechnologies with the technology developed during 15 years at Tel Aviv University by Prof. Tamir Tuller that is based on Artificial Intelligence and Big Data, which enables the fungus, yeast, or any other organism, to produce a larger quantity of protein from a single organism.

Imagindairy’s proprietary technology allows the manipulation of micro-organisms without touching the protein. The idea is to cause the fungus or yeast to be much more effective and achieve optimal productivity, thereby achieving the critical goal of cost that makes the product sustainable. And indeed, Afergan claims that as the research continues to progress, the company will be capable of producing alternative milk that is cheaper than cow’s milk.

“Our goal now is to enhance and accelerate the development processes in order to bring the first product to market during 2023”, Afergan says. “We believe that the best way to create real change is by collaboration and so we are developing products in conjunction with large companies from the milk industry. Together, we will offer the consumer an innovative and tasty product without using animals. This is the reason that we began working in the Strauss hub, which is also one of our investors, and although we have total independence, we are operating in full cooperation”.

Imagindairy doesn’t sell final products to the consumer. Its clients are large companies from the milk industry together with whom they develop alternative products. The penetration into different areas is performed based on an analysis of market potential versus willingness to adopt innovation and regulatory constraints. The initial goal is the US, but ultimately, we aim to reach the whole world.

“We are a biotech company that operates in the food-tech industry. These are very expensive technologies and therefore require significant resources. The Innovation Authority was our first investor, together with ‘The Kitchen Hub’. This was vital to the launch of the company says Afergan who adds that “The food-tech industry produces very innovative and attractive products… The food industry in general is undergoing tremendous change. We will gradually see more sophisticated, healthy, and tasty products on the market. The change will take several decades but it has already begun”.

Following extensive research, the Authority has identified the field of climatech as having the potential to grow an ecosystem that will lead to the cultivation of new Israeli startup companies in diverse areas, companies that will not only ride the wave of an economic business opportunity but will also benefit the world and mankind”.

Dror Bin, CEO of the Israel Innovation Authority